About us

Localizing seamless pipes manufacturing in the Middle East – in general, and in Saudi Arabia – in particular, was a commercial necessity and a strategic decision. Middle East and North Africa (MENA) is currently the most growing region related to Oil and Gas industry. GCC is having a strong demand for seamless pipes and various projects will sustain and even increase such demand in future. This regional development would benefit from a local supply of seamless pipes now that JESCO comes on stream.

JESCO benefits from its ideal location to deliver to GCC National & International Oil and Gas Companies, shortening their Supply Chain with thousands of miles and hundreds of days.

كان تحديد موقع تصنيع الأنابيب غير الملحومة في الشرق الأوسط - بشكل عام ، وفي المملكة العربية السعودية - على وجه الخصوص ، ضرورة تجارية وقرارًا استراتيجيًا.

وتعد منطقة الشرق الأوسط وشمال إفريقيا (MENA) حاليًا أكثر المناطق نموًا فيما يتعلق بصناعة النفط والغاز. كما أن لدول مجلس التعاون الخليجي طلباَ قوياَ على الأنابيب غير الملحومة ، وستحافظ مشاريع النفط والغاز المختلفة على هذا الطلب وستزيده في المستقبل حسب الخطط المرسومة لها. وسوف يستفيد هذا التطور الإقليمي من الإمداد المحلي للأنابيب غير الملحومة بعد أن بدأت شركة الجبيل لخدمات الطاقة "جسكو" في العمل والانتاج.

Mission

To provide the best quality products & services to our customers at competitive conditions, create value for our shareholders, transfer technology and create employment opportunities while remaining committed to quality, safety, social responsibility and environmental protection.

Products

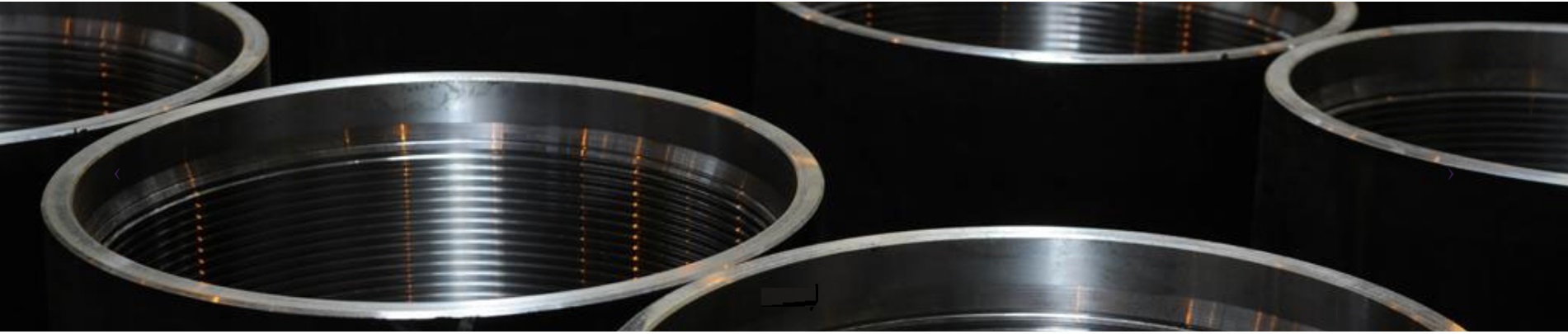

We produce Seamless Steel Pipes of various dimensions ranging from 4-1/2” to 16”. These Seamless Pipes are mainly used in the Oil and Gas sector. Our slated annual production rate is 400,000 Metric Tons (MT) of Seamless Line Pipes and OCTG products.

Infrastructure

JESCO is assured of uninterrupted supply of required utilities provided by the Royal Commission, Saudi Aramco, Saudi Electric Company and MARAFIQ.

Technology

JESCO has state-of-the-art FQM Technology provided by Danieli & C. Officine Meccaniche SpA of Italy. FQM technology allows JESCO to produce high quality pipes, with a high degree of production flexibility, versatility and efficiency. The FQM 3-roll retained Mandrel Mill has pronounced advantages over other seamless pipes manufacturing technologies, some of which are:

- Improved wall thickness tolerances.

- Improved pipe surface quality

- Improved pipe outer diameter accuracy

- Higher diameter to wall thickness ratios can be rolled

- Allows efficient use of larger range of sophisticated steel grades.

- High and low tonnages can be rolled, allowing order size flexibility and versatility

Through the latest heat treatment technology we are able to achieve API grades and tailored steel grades.

Our proprietary steel grades cover critical features such as sour service, high collapse, high compression or a combination of them all.

Quality

Our quality policy is an integral part of the company’s overall policies and strategies. This Quality Policy guides the organization towards continuous improvement to fulfill its mission.

- JESCO recognizes that continual improvement is key to sustainable success.

- JESCO is committed to ensure consistent compliance with its Quality Management System requirements which is continually reviewed and updated to improve its effectiveness.

- JESCO pursues policies which enhances its employee’s quality of life and preserve business relationships with its suppliers.

- JESCO maintains and makes every effort to improve the health and safety of employees and protect the environment.

- JESCO is committed to continuously evaluate, motivate, train and develop its human resources with particular emphasis to provide training to its Saudi Arabian employees.

- JESCO’s Quality Policy provides a framework for establishing, reviewing and measuring quality objectives.